A gentle method for 3D printing of biocompatible hydrogels

3D printing is currently undergoing very strong development for the design of objects with complex openwork shapes. However, this technology has some limitations for biocompatible hydrogels of very low density, which are particularly fragile. Researchers from the IMRCP laboratory, in collaboration with other scientists* from laboratories in Toulouse, have just overcome these limitations by developing a new method for 3D printing hydrogels for cell culture supports. These results are published in the Journal of Colloid & Interface Science.

For three-dimensional cell cultures, biocompatible hydrogels provide a soft, highly hydrated environment that approximates in vivo conditions. These hydrogels are essentially composed of water and a very small amount of biocompatible molecules serving as a structure. Specifically, the researchers behind this research are using hydrogels made up of small molecules that self-assemble into a very low-density network of fibres. This low density allows living cells to colonise not only the surface, but also the volume of the gel. But to build more complex architectures from these fragile hydrogels, it was necessary to develop a specific 3D printing method capable of shaping them without damaging them, as direct injection of the hydrogel is not possible because of its fragility.

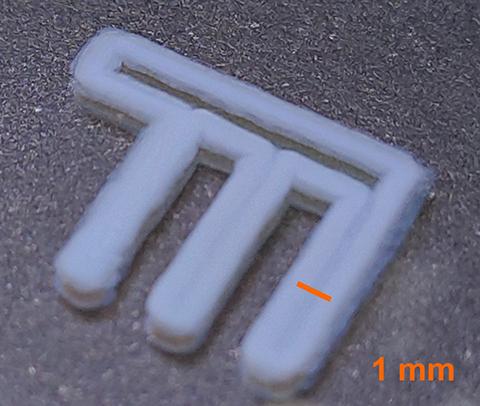

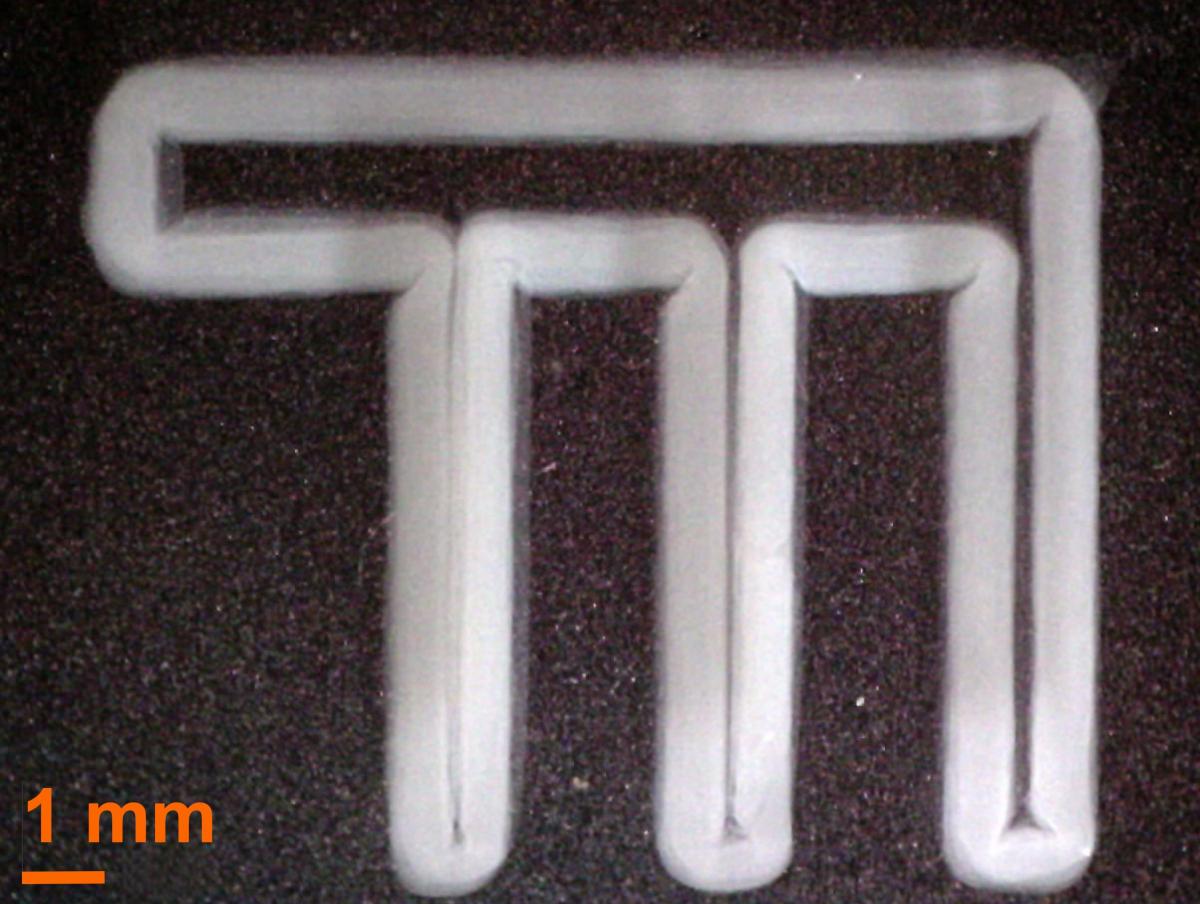

Juliette Fitremann and Faniry Andriamiseza from the IDeAS team have therefore developed a new technique in which a liquid solution of the gelling agent is injected into water, which leads to almost instantaneous setting of the gel on the printing site. This is due to the self-assembly of the gelant into fibres, which occurs extremely rapidly on contact with water. Patterns of perfectly controlled geometry can thus be produced with a simple vector drawing plotter or with a 3D bioprinter.

Juliette Fitremann and Faniry Andriamiseza from the IDeAS team have therefore developed a new technique in which a liquid solution of the gelling agent is injected into water, which leads to almost instantaneous setting of the gel on the printing site. This is due to the self-assembly of the gelant into fibres, which occurs extremely rapidly on contact with water. Patterns of perfectly controlled geometry can thus be produced with a simple vector drawing plotter or with a 3D bioprinter.

But the work does not stop there! The simultaneous injection of a water-soluble gel and a non-soluble gel allowed the formation of channels within the 3D printed hydrogel. Such channels are particularly important in the development of large-volume cell culture media, as they ensure the proper oxygenation and nutrition of the cells residing deep within the structure.

3D printed hydrogel ©Faniry Andriamiseza / IMRCP

These 3D printed gels also make it possible to envisage the design of new ultra-porous materials with perfectly controlled structures for applications in catalysis or electrochemistry for example.